Obtaining maximum benefit from a Fusion brazing or soldering alloy depends, in part, on fast, error-free application. The size and location of paste deposits can play a vital role in controlling costs, while insuring consistent joint quality. Fusion offers a range of applicators to achieve repeat accuracy, plus quick adjustment for varied part styles and sizes. Each includes an adjustable control panel, a pressurized paste reservoir, and a specially designed applicator gun.

Model 615 Applicator Controller

The Model 615 Applicator Controller is designed to dispense small deposits of paste brazing and soldering alloys or other viscous materials. Each paste deposit is precisely measured, ensuring controlled filler metal costs without waste.

FE-71 Applicator Gun

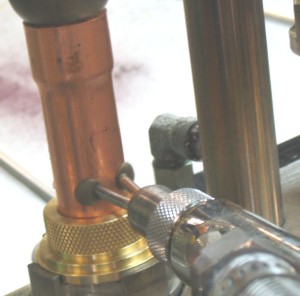

Fig I — Compressed air from control panel is introduced to upper gun body, forcing circular piston and attached piston rod upward against coil spring. Pressurized paste alloy (from reservoir) fills vacant space between piston rod tip and nozzle orifice.

Fig. II — As timer de-energizes, compressed air is exhausted, and coil spring returns piston and rod to closed position. Piston rod tip displaces paste alloy through nozzle orifice and seals opening until next cycle. Precise deposit size is obtained by adjusting control panel timer, paste pressure, and length of piston rod stroke.

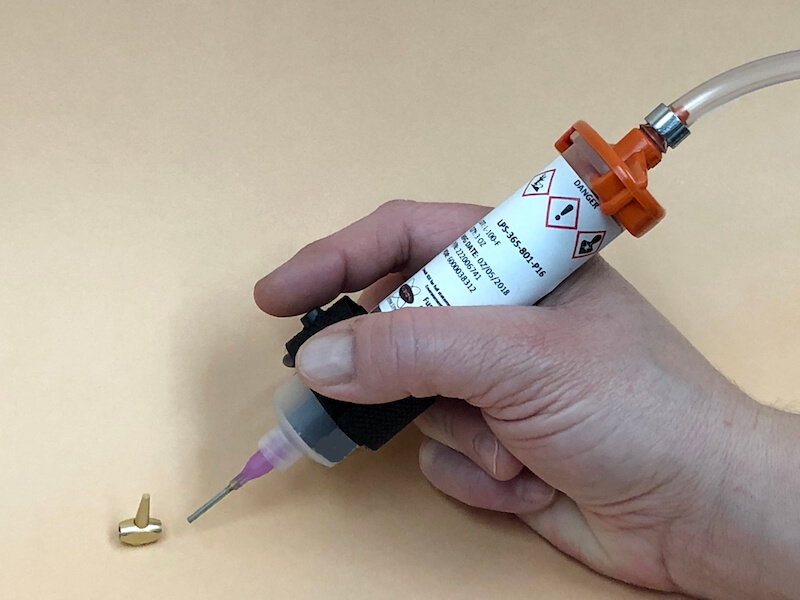

Pistol Grip Applicator Gun

Pistol-Grip Attachment allows paste to be applied manually to copper and brass assembly.

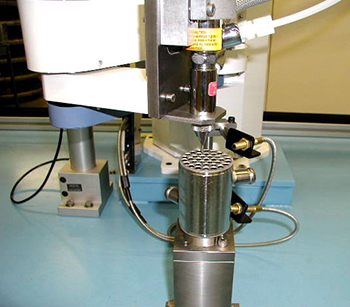

Satellite Paste Applicators/Robotics

Satellite Paste Applicators are designed to complement an existing heat source, such as furnace or induction. These freestanding units apply single, multiple, or “ring shape” paste deposits onto assemblies. Cycling is automatic and error-free with an operator removing the pasted part and loading it into the adjoining heat source.

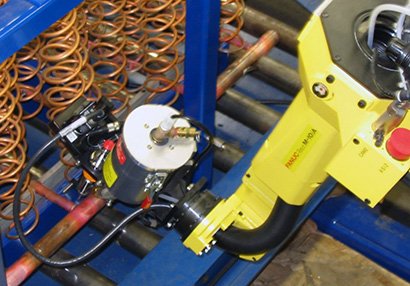

Applicator guns can also be mounted to a robot to apply a detailed combination of paste dots and stripes to a particular part. After the pasting cycle, the part is joined to its companion members and fixtured to the subsequent heating and cooling sequence.

Dual station system utilizes rotating mandrel technique to apply 360° stripe of Fusion Paste onto part joint area:

Two 360° stripes of Fusion Paste are applied to three-piece steel assembly utilizing “horizontal” rotating mandrel technique. After pasting, the assembly is loaded onto Fusion heating machine:

Robotic Paste Applicating System applies Fusion nickel paste accurately around 37 tube bundle/header assembly:

Guns, Reservoirs, Nozzles & Accessories

The Model FE-71 Applicator Gun is machine integration capable. Dispense premeasured deposits or stripes of Fusion Paste Alloy. Exclusive positive displacement principle ensures repeat accuracy for daily, trouble-free production.

R-100 Large Capacity Paste Reservoir

The R-100 Reservoir is recommended for applications where fast refilling and visual monitoring of the paste alloy level is desired. In production, the R-100 permits nearly 200 oz. of paste to be dispensed without interruption. Paste is packaged in special jars which incorporate a thin “follower” at the bottom.

USA: (440) 946-3300

EUROPE: +44 (0) 1279 443 122

Find Your Fusion Rep: USA | AMERICAS | EUROPE | ASIA-PACIFIC

Fusion Equipment in Action: Applications & Videos >>