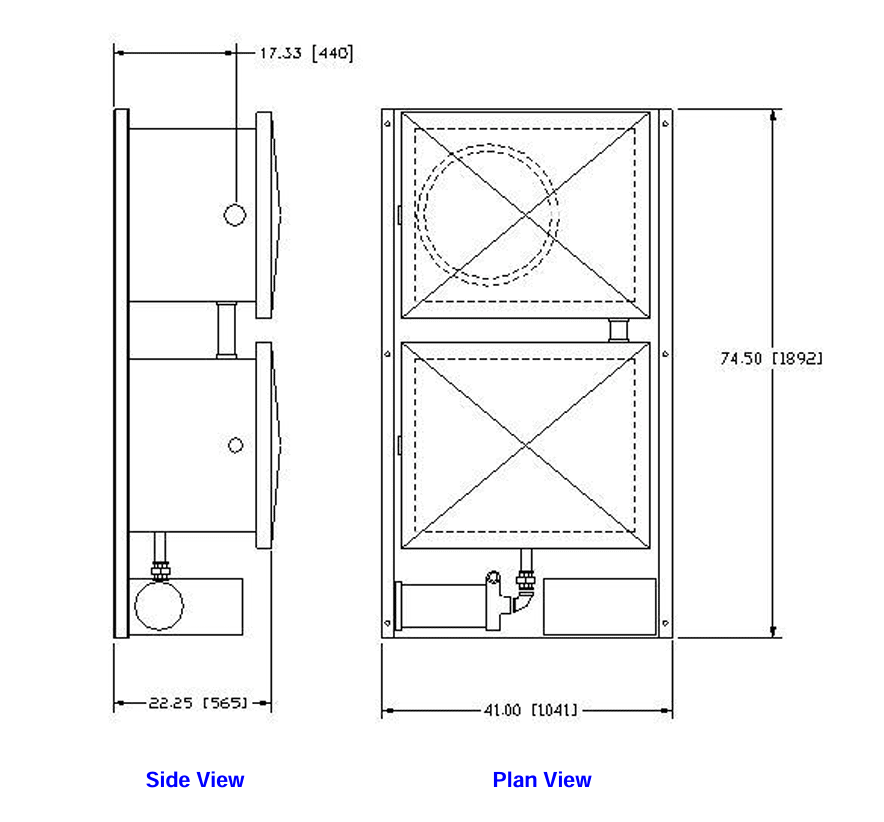

COOLING WATER RECIRCULATION SYSTEM 100 Gallon / 378 Liter Capacity

The Fusion Water Recirculating System is designed to be used with brazing and soldering machines. It can be easily retrofitted onto any existing machine or included as an option on new equipment. The closed loop system begins with an electric pump moving water from the first 50 gallon / 189 liter polypropylene tank. Water enters the brazing machine through the water inlet and onto the part to be cooled. Machine wastewater then drains back into a second 50 gallon / 189 liter tank and passes over a baffle to allow for sediment settling prior to repeating the cycle. The system incorporates a water replenishment feature to compensate for evaporation.

Specifications

Tank: Polypropylene with a temperature rating of 212°F / 100°C max.

Electric: 208-230/460V/ 3PH / 60 / 50Hz

Pump: 10 USGPM / 37 l/m capacity, ¾ HP motor, close coupled centrifugal, all bronze casing/impeller.

Weight: 450 lbs. / 204 Kg (without water)

Dimensions: See Reverse Side

The water recirculation system is designed to minimize water usage. (An average brazing machine uses 50 to 65 gallons / 189 to 246 liters of water per hour, therefore, the savings in water can be significant.) The frequency of draining the tank is based on many factors, such as the base metals of the parts being joined, the constituents in the brazing/soldering paste, the amount of paste being used, the number of hours (shifts) the machine is run, and the degree of impurities the local environmental regulations allow to be deposited in the sewage system. Due to the wide variations in all of the factors, it is not possible to precisely state when the water should be changed, but as a “rule of thumb” the frequency should be once per day. The system is not represented as a treatment system.