HVAC

HVAC systems are critical for climate control in buildings and structures. To keep system components securely connected, leak-free, and operational, they are usually joined by brazing or soldering. While these techniques are similar, they are not the same and are not used interchangeably.

At Fusion, Inc. we supply a variety of brazing and soldering paste alloys for HVAC components. We also design and build automated soldering and brazing machinery for production at scale. Learn more about HVAC brazing and HVAC soldering and the advantages they offer.

What Is HVAC Brazing?

HVAC brazing is the process of joining two components together, such as metal pipes or tubing. The first step is selecting an appropriate filler material, such as paste alloy, metal rods, or wire. These are usually made of a mixture of one or more atomized metals and a binder. A fluxing agent may or may not be included in the mixture, depending on the application.

After the components are cleaned, they are heated and the filler is placed between the parts. In HVAC brazing, parts are heated above 840°F, usually between 1100°F and 1500°F. The filler material bonds with the components and forms a new metal material that is exceptionally strong.

Brazed joints are leak-free and can withstand the high pressures, vibrations, and environmental stresses placed on HVAC systems over time. This method is compatible with a wide range of metals used in HVAC units, including dissimilar metals such as copper and brass or copper and aluminum.

What Is HVAC Soldering?

HVAC soldering is similar to brazing in that it uses heat and filler material, such as silver or tin, to permanently join components. The primary difference is that soldering takes place at temperatures below 840°F. While lower temperatures can preserve the strength of the components being joined, the resulting joints are not as strong as those created through brazing. Soldering is usually an appropriate choice for lower pressures and smaller pipes, including water supply or drainage lines.

Soldering’s lower temperature requirements also simplify the process:

- Nearby parts do not need to be protected from residual heat.

- A nitrogen purge isn’t necessary, for more efficient joining.

Both HVAC soldering and brazing have a place in HVAC manufacturing, modification, and repair applications, depending on application requirements.

Common Applications

Our quality paste alloys and custom automation solutions are ideal for a wide range of HVAC applications, including:

- Distributors

- Manifolds

- Suction Tubes

- Driers

- Mufflers

- Reversing Valves

Advantages of Brazing in HVAC

At Fusion, Inc., we provide high-quality standard and custom paste alloys for HVAC brazing applications. Brazing has several advantages for creating leak-free, strong joints, including:

Leak Prevention

Brazed connections can withstand high pressures and temperatures in HVAC systems. As a result, the system is less likely to lose air, gas, or liquid over time, and the system itself will continue to perform efficiently.

Strength and Durability

Brazing results in connections that are stronger, longer-lasting, and less vulnerable to damage or failure due to vibration. Not only does the high-temperature application create a long-lasting bond, but the joint interface that results from brazing is metallurgically linked to the base components, which adds to the overall strength of the assembly.

Versatility in Materials

Brazing processes are compatible with most metals, whether it’s a connection between similar or dissimilar metals. Paste alloys can also be formulated with different metals and materials for optimal results. Brazing can be used with metals including, but not limited to:

- Copper

- Brass

- Steel

- Stainless steel

- Aluminum

Advanced Techniques and Safety

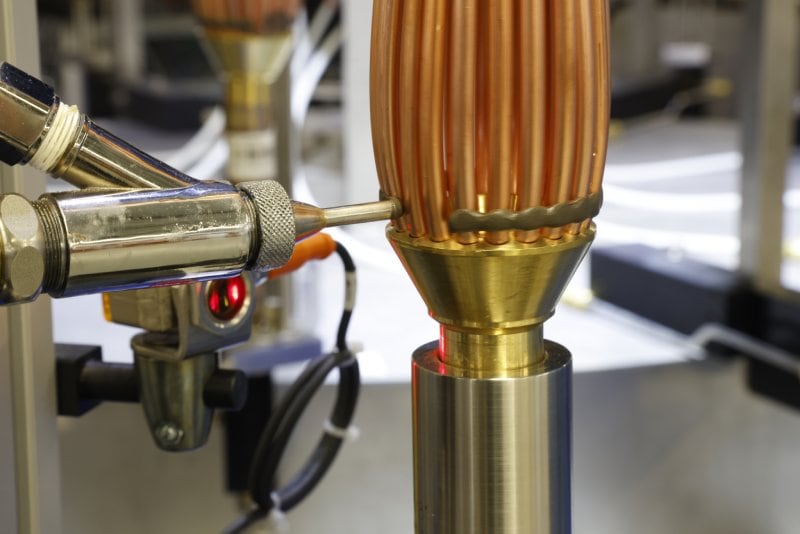

Induction brazing and resistance brazing are two common methods for joining components. Both provide extremely concentrated streams of heat and allow for high precision and great efficiency. Automated brazing equipment is another way to boost productivity and minimize variation in finished assemblies.

Cost-Effectiveness

Brazing is an affordable metal joining option because of the high performance it can deliver, which results in strong, long-lasting joints that need little maintenance over time. Joint durability and longevity also help save on the cost of consumables like filler metals and heating sources, such as gas or electricity.

High-Temperature Tolerance

Because brazed joints are created using filler metals with high melting temperatures, they can withstand operating conditions with high heat, high pressure, or other extreme environments.

HVAC Brazing & Soldering Services From Fusion, Inc.

Fusion’s brazing and soldering alloys are custom blended to meet your requirements for fast, single-step application, and eliminate the need to apply separate flux. Paste readily adapts to parts of different size or shape. A wide variety of formulations permit the joining of popular metals in the HVAC industry, including copper, brass, steel, stainless steel, and aluminum.

Looking to automate your brazing or soldering process? Let Fusion design and build you a solution! Reach out to Fusion or request a consultation to discuss your brazing or soldering alloy needs.