Automotive

When strict standards are required for your brazing application for automotive components, trust Fusion to deliver quality paste alloys and custom automation solutions.

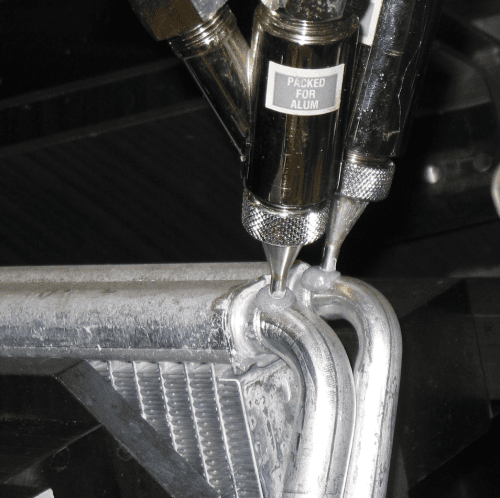

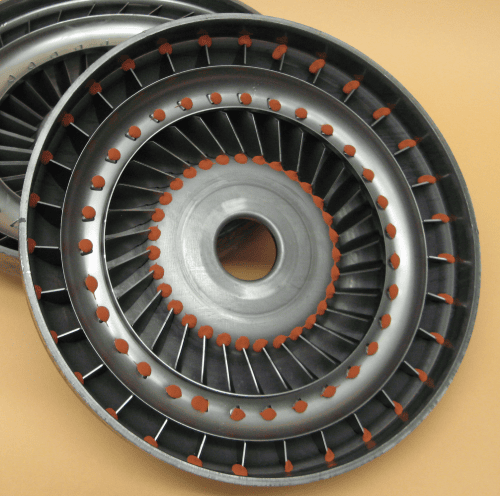

Common applications include: torque converters and other drivetrain components, battery components, heat exchangers and other HVAC components, and fuel system components.

Fusion’s brazing and soldering alloys are custom blended to meet your requirements for fast, single-step application, and eliminate the need to apply separate flux. Paste readily adapts to parts of different size or shape. A wide variety of formulations permit joining of popular automotive metals, including copper, aluminum, stainless steel, and steel.

Reach out to Fusion to discuss your brazing or soldering alloy needs.

Looking to automate your brazing or soldering process? Let Fusion design and build you a solution!