Tooling

Fusion understands that the quality of brazed joints is crucial in many cutting, shaping, and material removal tools. Our brazing paste products are easy to work with and are highly compatible with automated brazing equipment, for efficient tool manufacturing. Trust Fusion to deliver quality paste alloys and custom automation solutions.

Keep reading to learn more about the brazing process, how it is used in tool manufacturing, and its benefits.

What is Brazing and How is it Used in Tool Manufacturing?

Similar to soldering and some types of welding, brazing is a process that joins two or more metal surfaces when molten metal filler material flows into the joint between the base metals. In contrast, however, While welding melts both the filler and base metals, brazing only melts the filler metal, leaving the base metals intact.

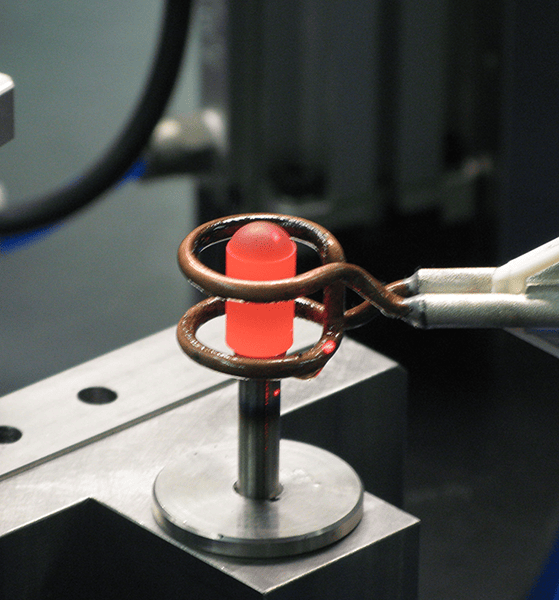

Filler pastes are often used for brazing operations because they include powder metal, flux, and binders in a single product and can be applied easily in a single application and with an automated dispenser. This results in efficient manufacturing and very little waste.

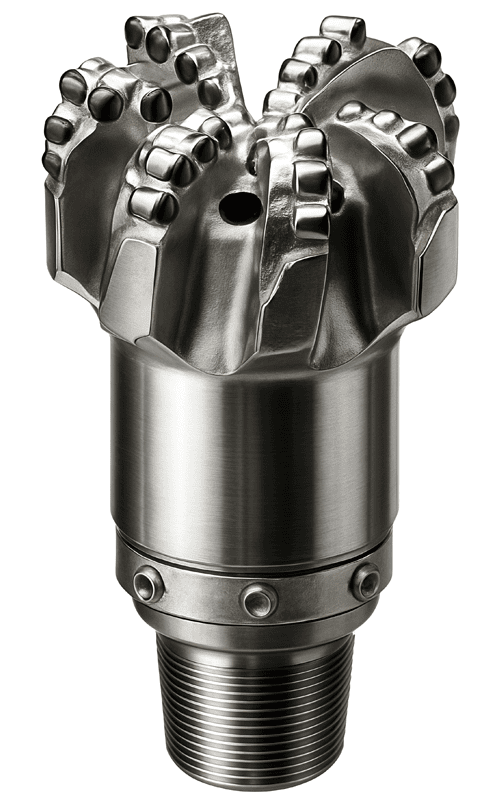

In brazing, the filler paste is placed between two matching or dissimilar base metal pieces to be joined. It melts and reacts with the pieces, and that reaction creates a thin layer of a new alloyed material called the joint interface. Brazed joints are very strong and have no voids, which is important for cutting and material removal tools. In many applications, these tools must withstand strong forces and cut into hard materials, and the strength brazing provides is essential.

Brazing Paste for Tool Manufacturing

Brazing pastes, such as Fusion’s selection of brazing paste products, are widely used in tool manufacturing, and are valued for their ease of application and compatibility with automated brazing equipment. They can also be used to join dissimilar metals, such as tungsten carbide and steel.

Due to the high integrity of brazed joints, tools made with this technique are used in many different cutting, shaping, and material removal applications. Some common examples are:

- Woodworking: Saw blades, drill bits, router bits for hard and soft woods.

- Natural Stone Cutting: Blades and drills for marble, granite, quartz.

- Concrete Work: Cutting, drilling, coring tools.

- Machining Ferrous and Non-ferrous Metals: Milling, boring, drilling, precision and finishing cuts in steel, aluminum, copper.

- Machining Plastics: Cutting, drilling, routing standard and reinforced polymers.

The Advantages of Brazing in the Tool Manufacturing Industry

Compared to soldering and welding, brazing provides several key advantages in the tool manufacturing industry, such as:

- Lower power input and processing temperature than welding.

- Joints with minimal thermal distortion and residual stresses than welding.

- Base metals don’t melt and retain their shape and mechanical properties.

- No post-processing heat treatment required.

- Compatible with dissimilar base materials.

- Stronger joints than soldering.

- Convenient brazing pastes streamline the joining process.

- Brazing paste contains flux that removes oxides from the base metals to create a smooth and strong bond.

- Easily automated for high production rates.

Brazing Solutions for the Toolmaking Industry from Fusion, Inc.

Fusion, Inc. is a leader in brazing paste and automated brazing technology. In addition to a variety of pastes and applicating equipment, our team develops, tests, and sells custom automated brazing machines and systems.

If you are interested in automating your brazing process for tool making or other applications, contact us to learn about our capabilities, or request a consultation to get started!