Automotive

Brazing and soldering are two joining processes that use heat and filler material to permanently bond metal parts. Both are widely used for automotive applications where strong and durable bonds are required, including drivetrain systems, radiators, and more.

Fusion, Inc. provides custom brazing automation solutions, brazing and soldering supplies and equipment, and automotive industry knowledge and expertise. Learn more about the role these two techniques play in automotive and vehicle applications, and how Fusion supports them.

Brazing in the Automotive Industry

Motor vehicle systems and assemblies are subject to extreme temperatures, vibrations and shock, and heavy use; therefore, the techniques used to join components must be durable and suited to these harsh operating conditions. Brazing creates a strong, permanent bond between metal surfaces including aluminum, stainless steel, and copper alloys. Because it is effective at joining dissimilar metals, brazing is a common choice in applications where welding or soldering cannot. Many vehicle systems benefit from brazing, including:

- Heat exchangers

- Safety components such as door hinges and airbag brackets

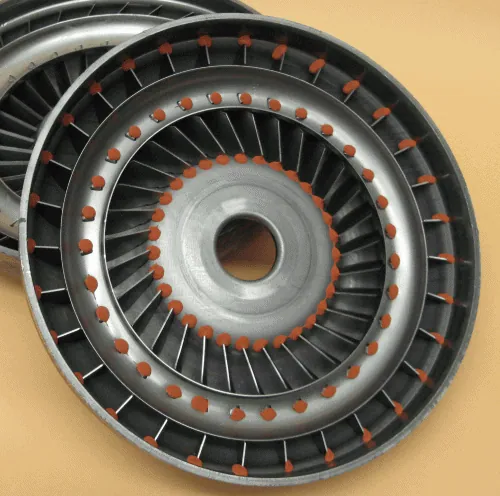

- Torque converter parts

- Fluid transfer systems for brakes, fuel, and power steering

- Exhaust systems

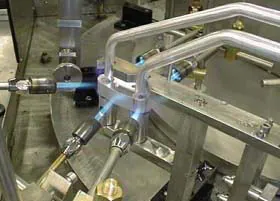

Both traditional (flame or torch heated) and induction (electromagnetically heated) brazing can be used with filler metals or brazing paste to create strong bonds. Pastes have the advantage of being easy to incorporate into automated brazing processes, including high-volume production. This can result in greater precision and efficiency for manufacturers.

Soldering in the Automotive Industry

Soldering involves applying heat to metal components and a filler metal to create a durable bond. It is commonly used in automotive applications, especially where high-temperature processes, like welding or brazing, are not suitable. Electrical and electronic components, radiator repairs, and body work are common soldering applications.

Advantages of Soldering and Brazing in the Automotive Industry

Both soldering and brazing offer advantages for auto manufacturing, including:

- Permanent or temporary bonds. Brazing is typically used for permanent bonds, while soldering can be used for temporary or permanent joins.

- Versatility. Brazing and soldering are ideal for joining both similar and dissimilar metals, though not all solders are suitable for dissimilar materials. Parts of varying size and thickness are also easily joined.

- Durability. Brazing creates high-strength, permanent bonds that can withstand the vibration and impact stresses of automotive applications.

- Minimal component damage. There is a low risk of damaging parts and components due to heat since the base metal components are not heated above their melt points. The heat affected zone (HAZ) may also be smaller with brazing or soldering than with welding.

- Efficient. Both processes use lower temperatures than welding, which means less energy is required. Both can also be automated for faster cycle times and high-quality joins with minimal errors.

Automotive Industry Brazing & Soldering Solutions From Fusion, Inc.

When strict standards are required for your brazing application for automotive components, trust Fusion to deliver quality paste alloys and custom automation solutions.

Common applications include: torque converters and other drivetrain components, battery components, heat exchangers and other HVAC components, and fuel system components.

Fusion’s brazing and soldering alloys are custom blended to meet your requirements for fast, single-step application, and eliminate the need to apply separate flux. Paste readily adapts to parts of different sizes or shapes. A wide variety of formulations permit joining of popular automotive metals, including copper, aluminum, stainless steel, and steel.

Reach out to Fusion to discuss your brazing or soldering alloy needs.

Looking to automate your brazing or soldering process? Let Fusion design and build you a solution!