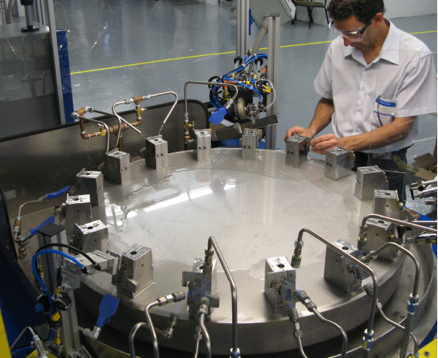

Fusion specializes in automated brazing equipment for metal joining applications. The most popular machine is the Rotary Index style, used for most automatic soldering and brazing applications. The typical sequence on this piece of brazing equipment begins with manual or automatic loading of parts onto fixtures. Indexing clockwise to the next braze station, the parts are pasted by one or more automatic dispenser guns. These brazing equipment guns, generally mounted on slides, apply a pre-measured deposit of paste alloy to each joint. After pasting, the parts index through three to five heat brazing stations, followed by an air and water cooling sequence.

Lower volume brazing equipment includes the Braze Mate, an ideal brazing machine for low volume applications or short runs of various part styles. For this brazing station, a fixed pattern of gas/air burners advances into heating position. Oscillating flames eliminate “hot spots” at the assembly joint area. Once joining temperature is reached, the burner manifold retracts into idle position. A gradual air and water cooling sequence is followed by manual part inspection and final unloading.

For those who don’t want to heat with flame, induction heat is a good alternative as a brazing equipment choice. Induction creates a rapid, localized heat, recommended for carbides and heavy mass parts. Fusion can work with an induction vendor of your choice and integrate their brazing equipment into our machine design. Brazing stations can also be controlled by robotics which can handle brazing paste application, and heating functions. Brazing equipment of this nature is ideal for assemblies with multiple brazed joints.

USA: (440) 946-3300

EUROPE: +44 (0) 1279 443 122

Find Your Fusion Rep: USA | AMERICAS | EUROPE | ASIA-PACIFIC

Fusion Equipment in Action: Applications & Videos >>