The Rotary Index style machine is the most widely used for most automatic soldering and brazing applications. The typical sequence on a rotary machine begins with manual or automatic loading of parts onto fixtures. Indexing clockwise, the parts are pasted by one or more automatic applicator guns. These guns, generally mounted on slides, apply a premeasured deposit of paste alloy to each joint.

After pasting, the parts index again through a series of natural gas/air burners. The burners progressively heat the assembly to the liquidus temperature of the filler metal. Following heating, the part indexes through a series of cooling stations. Both air and water are used to solidify the alloy and bring the part and fixture back to room temperature. The finished part is then automatically ejected or manually unloaded by the operator. Production rates between 100-1200 parts per hour are typical.

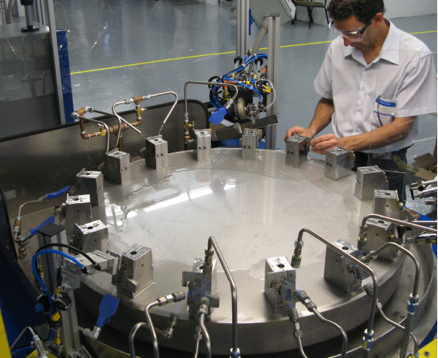

Rotary Index 200 system conveys fixtured parts

through brazing alloy application,

heating and cooling cycles.

Fusion offers three basic rotary index machine models:

Rotary Index 100

- Dimensions: 48″ x 48″

- 8-station maximum

- Aluminum structural frame

- Typical Rate: 100-200 parts per hour *

Rotary Index 100/120 Standard Features >>

____________________

Rotary Index 120

- Dimensions: 60″ x 60″

- 8-12 stations

- Welded steel frame

- Typical Rate: 100-200 parts per hour*

Rotary Index 100/120 Standard Features >>

____________________

Rotary Index 200

- Dimensions: 72″ x 72″ or 80″ x 80″

- 10-24 stations

- Welded steel frame

- Typical Rate: 300-1,200 parts per hour *

Rotary Index 200 Standard Features >>

* These figures are general and may depend on part size, complexity, and weight.

Although most of Fusion’s automatic soldering and brazing machines employ open flame heat, alternative heat sources can be used, such as induction or resistance. Induction creates a rapid, localized heat — recommended for carbides or heavy mass parts. Resistance heat is ideal for joints that require intense, localized heat without annealing. These heating methods are out-sourced and incorporated into Fusion machine designs.

With Fusion Machines, joint quality is virtually guaranteed, due to the elimination of human error. Material costs are controlled, since filler metal and flux are applied automatically — in just the right amount. Labor costs become insignificant, as one operator turns out hundreds of brazed or soldered assemblies per hour.

TYPICAL MACHINE SEQUENCE

- STATION 1 – LOAD/UNLOAD

- STATION 2 – PASTE

- STATION 3 – OPEN

- STATION 4 – HEAT

- STATION 5 – HEAT

- STATION 6 – HEAT

- STATION 7 – AIR COOL

- STATION 8 – AIR COOL

- STATION 9 – WATER COOL

- STATION 10 – OPEN

12-station machine

- 300 parts per hour

- One operator

16-station machine

- 600 parts per hour

- No operator required

- Vibratory bowls feed and place components

- Brazed parts are automatically ejected

USA: (440) 946-3300

EUROPE: +44 (0) 1279 443 122

Find Your Fusion Rep: USA | AMERICAS | EUROPE | ASIA-PACIFIC

Fusion Equipment in Action: Applications & Videos >>